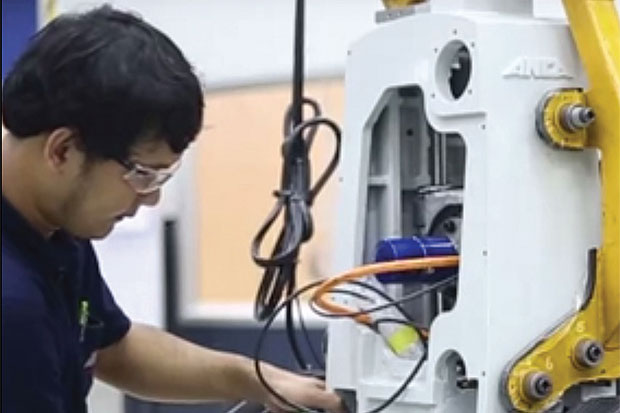

Anca Manufacturing Thailand, a subsidiary of Melbourne-based Anca Group, has expanded and upgraded its production facility to serve high numbers of purchase orders in the country.

The world’s leading maker of computerised numeric controls (CNC) plans to almost double its production capacity to 85 CNC units per month from 45 units now.

The company has allocated 800 million baht to expand production capacity and it has also relocated the plant from Hemaraj Eastern Seaboard Industrial Estate to Amata City Industrial Estate in Rayong.

Yanisa Ninlawong, general manager of the local unit, said the new plant is expected to open in August and this facility will be the second-largest Anca production site in Asia-Pacific.

She said the local unit will be upgraded to a full CNC assembly, along with Anca’s plants in Australia, and the labour force will be increased to 280 persons from 150.

The new site was granted Board of Investment (BoI) privileges because it is located in the flagship Eastern Economic Corridor.

The CNC is machinery that can be used for medical purposes, telecommunications, information technology, automobiles and woodwork.

CNCs can also be applied to the production of aerospace components, which is among the 10 targeted industries under the government’s S-curve model.

“Our upgraded plant and new expansion in Thailand will get full support from the government through the BoI and create new jobs in Rayong,” she said.

Ms Yanisa added the company recently signed a memorandum of understanding with the Institute of Field Robotics (Fibo) under King Mongkut’s University of Technology Thonburi (KMUTT) to increase human capital levels and avert any future problems of labour shortages.

The signing ceremony was done in Bangkok last week by KMUTT president Assoc Prof Sakarindr Bhumiratana and Anca Group chief executive Grant Anderson.

She said workers at the new plant will be capable of designing, researching and developing innovative products, making it crucial to secure plans for human resources because Anca always has new models and new technological developments for CNC.

Fibo is a state-owned unit that develops skilful students and gurus in robotics. Fibo has 80 students annually.

Assoc Prof Djitt Laowattana, the founder of Fibo, said both parties will exchange and transfer know-how on robotics and share research findings. The students are expected to benefit from work experience and training at Anca.

Assoc Prof Djitt said the exchange is another big step in robotics knowledge and automation systems for Fibo, allowing students to be more practical, in line with Fibo’s purpose - work-integrated learning.

Fibo has 120 graduate students, of which 90 are undergraduates and the rest are post-graduates.

Thailand has some 8,200 people involved with robotics and automation, comprising technicians, engineers and lecturers in the mechanics and electronics fields.